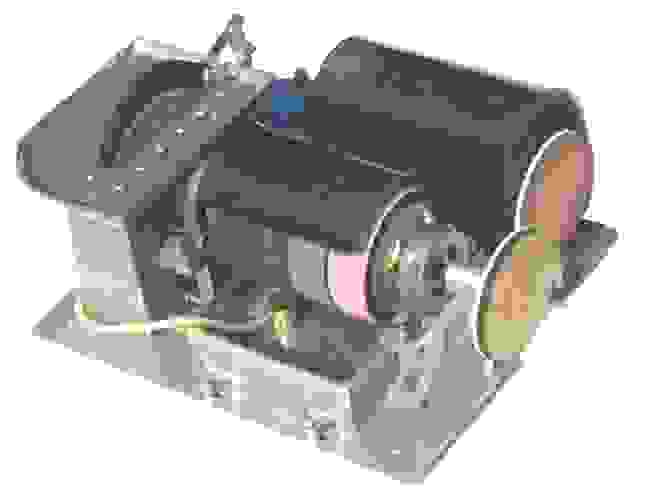

miniCutter

Design.....Features....Benefits

Designed by a Gem Cutter for Gem Cutters !

Design and Development

As a gem cutter for over 11 years, an opal cutter for 8

(as a member of the American Opal Society),

I found myself cutting gems--not bookends or belt buckles--that were

seldom bigger than my thumbnail. I began to wonder why I needed

something nearly 3 feet long to create a half-inch gem!

And sometimes-- sunny days, for example--

I didn't want to cut on the workbench, but on the patio,

even on the dining table one evening.

I wanted something I could even take on the road, to club workshops,

in my little trailer…to the gem shows.

Same reason you grab your laptop computer,

instead of the desktop model...

I wanted something portable, professional, and powerful!

So, a gem cutter designed a gemcutter—a miniCutter!

Why only 4 wheels? As I began to cut opal, turquoise, sunstone, and other gems,

I found that I seldom started on the 100g wheel, but more often the 220g or even 280g,

especially with opal. A "softer" start meant you didn't accidentally cut

through the fire layer in that black crystal opal!

I found I often needed a trim saw more than I needed coarse grinding wheels!

So, I chose the saw over the coarse wheels, and to my surprise, when I tried

a 220g NOVA on it, I could also shape agate

and other gems with a Mohs hardness of 7 or so!

Takes a little longer, yes...but the trade-off for portability is worth it to me--

to have all the basic functions of gem-cutting in one portable miniCutter!

Saw, grind, sand and polish--even buff--if I had to take

one gem maker to a desert island, this would be it!

So, opal cutters might use the miniCutter with a wheel sequence of

280g, 600, 1200, and 3,000,

while agate cabbers might go with

220g, 600, 1200 and 3,000

and then to the polish laps.

I get a nice glossy finish on most agate I've cut--

Holley Blue, Laguna, red flame, Coyamito, chrysoprase, etc.--

with 3,000g followed by a 14,000g lap polish!

So, I trade some extra shaping time for portablity!

And what portability! Under 24 lbs...in a 14" footprint!

The miniCutter is about as wide as your laptop computer--

with a 5" trim saw built-in!

And handles for those of us who'll never be Olympic weightlifters!

Now I cut in the kitchen, on the patio, at the club workshops--

I throw my machine in the trunk

and run it off my Honda generator at the gem shows between sales!

The miniCutter features small things I like in a cabbing machine:

an AC outlet for two additional items—pump and a lamp, say.

Storage for an alternate polish lap.

An optional “rip plate” for slabs too large to fit on the table.

Handles for easy transport. An optional tote carrier

for even easier transport to and from the car!

A blade guard easily removed, or used with Rip plate

to accommodate longer cuts. Twist-nuts to speed blade changing.

And more!

"CONSTANT CUTTING"

But the best feature of the miniCutter is “Constant Cutting.”

Whether I'm cutting an opal or an Oregon sunstone, I hate to break away

and go to a trim saw, or change a belt or a wheel set, and interrupt my focus...

a real "gumption killer!"

I want ALL my blades and wheels running constantly--constant cutting--

so I merely move the stone back a wheel, for a spot I missed, or forward to polish,

without some exercise in mechanical aptitude!! The miniCutter has ALL functions

operating ALL the time--trim, grind, sand and polish at will, no waiting!

Constant functionality to keep you cutting a gem,

not hunting for a wrench!

Opal cutters, especially, will find the miniCutter a delight,

as they move back and forth over the wheel sequence.

[Side note; When I researched, I was astonished to find that not only is

there no other portable cutter that features this "constant cutting" action, but there

aren't even any bench models that do! The miniCutter gets you from rough to

finished gemstone without breaking that "zone" that you get into when you're chasing

a fire layer through some Lightning Ridge crystal opal!]

RETRO DESIGN

The design philosophy is a salute to the retro simplicity of lapidary cabbers

of the 60s, the Highland Park-, Frantom- and Star Diamond machines

that were built simple and sturdy, and seemed to last forever. Metal,

where it makes sense, and plastic--as little as possible--where it makes sense!

But more important is that simple design also means simple SERVICING of these machines...

they are designed so most any handyman can make simple repairs or replacements

with common tools, and common skills.

The simple design, combined with modern diamond wheels, and XL drive

components,make the miniCutter powerful, flexible, precise, durable,

and simple to service. Belts, pulleys, arbors are all standard American parts,

manufactured here in the USA, and servicible locally, as well as through factory service.

Some techies and old-timers will tell you that a machine

with a single speed (approx 1500 rpm)

can’t provide the correct speed for sawing, grinding, and polishing.

Ideally, a cabbing machine should have a fast saw speed, medium wheel speed ,

and slow polishing at the lap. Theoretically, they are correct.

But when this little quibble comes up, I simply pull out the amazing opal cabs,

Carnelian, sunstone, and Royston turquoise I’ve made on the miniCutter.

If the proof of the pudding is a beautiful glossy polished gemstone,

well, I’ve got them! After they’ve seen the gems, I don’t hear much of

this concern again!

The diamond wheels provided are Diamond Pacific NOVA wheels--identical to

their Pixie wheels--which I've never seen surpassed for quality and longevity.

The arbor shaft will accommodate any 4” wheel with a 1” bore (center).

The goal? Allow the gemcutter every opportunity to outfit, service and upgrade

his machine himself, and not lose 3-4 weeks of time and expense shipping and

re-shipping a unit, or a part. Web-based service .pdfs and videos will also be available...

free to owners!

SPECIFICATIONS

Motor: 1/8HP Dayton 1 year Mfr's. warranty

Drive XL cog pulley

Shaft : 5/8” ball bearing arbor, with 1” alum sleeve adaptor

Saw: 5” trim saw w sintered MK BD diam blade, .020

Wheels: (4) Diamond Pacific NOVA Flex

220g or 280, 600, 1200, 3,000g

Irrigation: Air pump, single brass geyser

AC outlet: x 2… Built-in

Polish Lap: 4” canvas w 14k diamond paste 2 gms

Tank, Tray, Table, Base: aluminum Hoods, Blade Guard: polycarbonate acrylic

Dimensions: approx. 14” L x 12 D x 8” H

Weight 24 lbs. Ship weight: 27 lbs

Warranty: 180 days labor, 1 year parts [excluding expendables e.g., wheels, blade, laps]

I hardly use my large bench cabber anymore...it's like going back to a grand piano,

when my portable keyboard makes beautiful music too!

The miniCutter was in the prototype stage for about 8 months, demo'ing at the American Opal Society, Quartzsite Powwow, the Victorville Tailgater, the Vista Tailgate show, and the Torrance show to enthusiastic crowds.

When two miniCutters were demonstrated at the Jan 2011 American Opal

Society meeting, the comment in the next monthly newsletter was:

“Members practice[d] cutting and polishing on [the] machines....

most were impressed by the compact size of the unit,

and its versatility!"

The comments I get at the shows are generally "Cool!" and often

"I could put that in the RV!!" ,

quite unsolicited from me! I had several folks ready to put in orders at the Powwow, before I was even ready to "price"the unit out retail!

Raves and Reviews

Jewelry Artist Review March 2012

"This Machine ROCKS !!!"

Email us for a .pdf copy of this review,

and others...

Rip Plate Option [ $ 39.99 ]

The miniCutter is currently in use by many satisfied gemcutters!

Let us build one for you ! All miniCutter parts and accessories are interchangeable and standard--but each machine is carefully constructed to your needs, so if you're in a big hurry, don't be!

Allow 4-6 weeks for delivery. That gem silica rough has been waiting 100,000 years for you to make it a gem--a few more weeks will be well-worth waiting for!